How to distinguish Anti-foaming agent added or not in PVA!

It’s kindly of simple to tell apart whether anti-foaming agent added or not.

Here we have below three ways you can try:

Notice:

No special requirement on concentration in below testing, normally 4%. Anti-foaming agent can

works with any concentration.

Please keep the same conditions in the control group

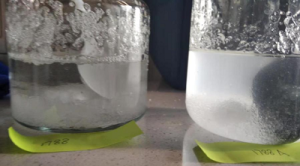

1. Observe the solution after dissolution.

The picture shows PVA sample with oily anti-foaming agent. (whether the water-based AF agent

will reflect this feature remains to be verified)

1788A (with AF agent), AF agent would make the solution muddy and opaque

1788(without AF agent), the solution is transparent as water

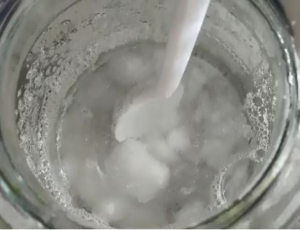

2、After proper dissolution, stir the solution and observe the foaming and defoaming conditions

| 1788, 15mesh, without anti-foaming agent | 1788A, 15mesh, with anti-foaming agent |

| After stirred, there are more bubbles, and the bubbles do not disappear for a certain time | After stirred, a small amount of bubbles will appear, and what can disappear quickly |

|  |

| Foaming will be more obvious if PVA particle size is finer (tested by buyer,2488,mesh size 15-20) | |

|  |

3、 After heating, the performance characteristics of foam will be more obvious

| 1788A,15mesh,with anti-foaming agent | 1788,15mesh. Without anti-foaming agent |

| After heating to above 90 ℃, a small amount of bubbles will appear, and defoaming will be faster after heating is stopped | After heating to above 90 ℃, foaming is very obvious, and defoaming is slow after stopping heating, the foaming would stay for a certain time |

|  |

|  |